By: PinkPenguin1988

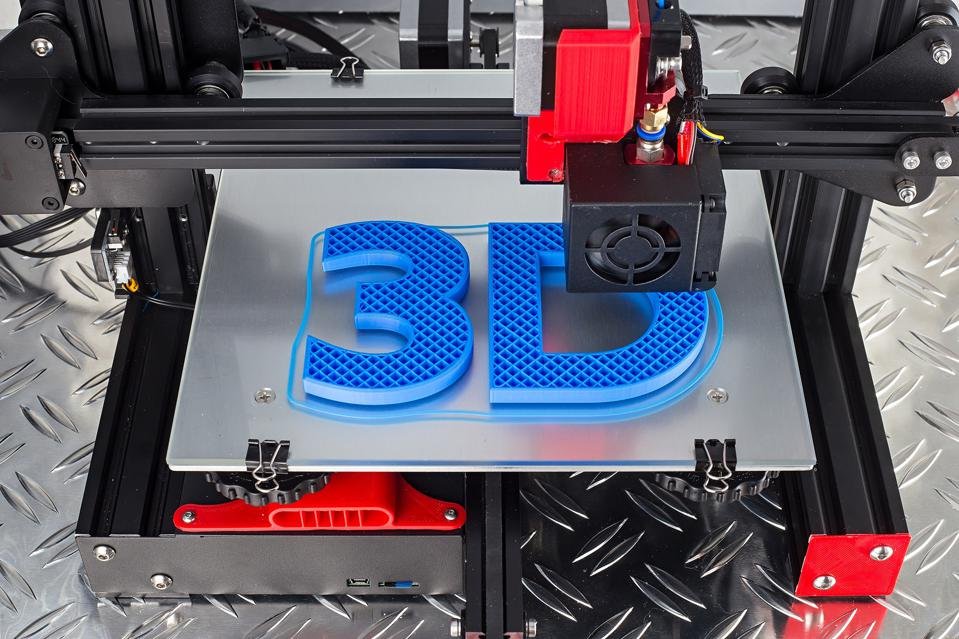

Some of you may be asking “What are the future trends of 3D printing? in My opinion soon enough 3D printing will be bigger, faster and cheaper. Why do you ask? The key for the new generation of printers, especially industrial-grade solutions, will be the ability to handle a greater range of advanced materials. This opens the door for businesses to benefit from additive manufacturing in areas where they previously could not. Which is already an amazing advancement within itself. I drove around last weekend and drove by them building 3D Printer.

Building technology and development are constantly evolving. It’s our responsibility within the industry to stay up to date, learn, and incorporate these fast-developing systems into our professions. 3D printed technology has helped many industries and has now made its way into construction. Let’s take a look at a couple of powerhouse companies using it well.

As stated in the architecture journal One Austin-based company, Icon, has teamed up with 3Strands to develop the first 3D printed home community for sale in North America. Homes ranging from 900 to 2000 sq. ft. outside of Austin are the first of their kind but certainly not the last. All four homes feature large covered front porches, covered parking, open concept floor plans, custom-made interior design, Large master bedrooms, North-facing windows, secluded office/bedrooms, and minimalist design aesthetic. In its first year 2017, Icon teamed up with the nonprofit group, New Story, to print a 350 square foot home in just 48 hours as a proof of concept for housing solutions in developing countries giving people shelter quickly who normally would have trouble getting housing or simply didn’t have the space. providing warmth and shelter to those in need. They went on to build a 3D-printed community of homes in Tabasco, Mexico. They have partnered with the US military to construct barracks outside of Austin and have received funding from NASA to collaborate with world-famous architecture firm BIG to create a 3D printed habitat that “support[s] long-duration, exploration-class space missions” giving them at home time more often.

Mighty Buildings, another construction technology company working in Oakland, has been successful at 3D printing and assembling many micro-units since the company was founded in 2017. They have continued their growth with the “first 3D printed zero net energy community” featuring mid-century modern architecture near Palm Springs (https://mightybuildings.com/projects/rancho-mirage). Each of the 15 properties has a pool, an ADU, and options for certain upgrades, such as cabanas and hot tubs.

Of course, we can’t look at this technology and not think of what the repercussions to the industry might be, both good and bad. I’ve listed just a few to think about.

Buyer Trends: Buyers are expected to provide feedback and be a part of these communities. According to Zonda’s housing trends survey, technology continues to be highly demanded in homes and 58% of buyers want a “somewhat more modern architectural style.” Buyers value interesting contemporary architectural designs, and 3D printed technology can execute various desired shapes and a clean look with impeccable and consistent precision.

Labor Impacts: There will be fewer on-site accidents, but equipment requiring full-time monitoring also involves extensive training. Additionally, as such reliance on technology increases, the number of traditionally skilled craftsmen and trades will continue to be in perpetual decline, which can cause employment problems for people in the future, hence where the fear of robotics in a lot of restaurants and stuff comes in as well.

Environmental Impact: By limiting excess material and not requiring formwork, concrete will be used more efficiently, creating less construction waste.

City Regulation: Inevitably, when new technology or trends arise, codes and regulations follow; cities must invest time and energy to update their codes to incorporate these new methods of building. which isn’t always easy for some cities, specially the smaller ones, which can in turn cause stress on the community.

Let’s take a look at a couple of powerhouse companies using 3D printing to its advantage. One Austin-based company, Icon, has teamed up with 3Strands to develop the first 3D printed home community for sale in North America. Homes ranging from 900 to 2000 sq. ft. outside of Austin are the first of their kind but certainly not the last. “All four homes feature large covered front porches, covered parking, open concept floor plans, interior design, huge master bedrooms, large windows, secluded office/bedrooms, all this with minimum actual wood, or construction. The best part of this story! In its first year 2017, Icon teamed up with the nonprofit group, New Story, to print a 350 square foot home in just 48 hours as a proof of concept for housing solutions in developing countries, meaning they should now be able to travel to those less fortunate then us and helped build homes to help more and more people survive. They went on to build a 3D-printed community of homes in Tabasco, Mexico. Today, the company continues to diversify. They have partnered with the US military to construct barracks outside of Austin and have received funding from NASA to collaborate with world-famous architecture firm BIG to create a 3D printed habitat that “supports long term exploration-class space missions” keeping them at a home longer.

Just like any new technology, there will be growing pains, but this seems like it is here to stay. Keep an eye out for how these companies and others continue to push the boundaries in construction. and remember keep printing!!!

PinkPenguin1988: Kyrons3DPrinting

Leave a Reply